For those who are interested in becoming a crime scene cleaner, you should know that there is no formal education needed to be one. However, a lot of bioremediation companies offer OSHA training and on-the-job education sessions.

A Few Training Programs of Crime Scene Cleanup

- Bloodborne pathogen training

- Personal protective equipment (PPE) training

- Respiratory protection training

- Hazardous communication training

- Medical waste handling and transporting training

- Heat-illness awareness training

The first one, bloodborne pathogen training, is also known as OSHA certification as it is given by OSHA or Occupational Safety and Health Administration. This training may be needed to complete some specialized training before starting your career as a crime scene cleaner.

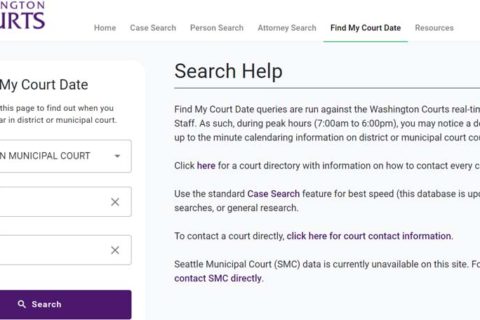

One again, in order to start the cleanup process of a crime scene, you do not have to get a license or certification. However, you are required by Occupational Safety and Health Administration or OSHA to follow its Blood borne Pathogens standard or BBP. For those who have no idea about Blood borne Pathogens standard or BBP required by Occupational Safety and Health Administration or OSHA, you can check out the following information.

Bloodborne pathogens are known as the infectious microorganisms that are found in the blood. They can cause disease in humans so they are clearly dangerous. These pathogens include hepatitis B virus or HBV, hepatitis C virus or HCV, and human immunodeficiency virus or HIV, the one that can cause AIDS. However, they are not limited to that. If a worker is exposed to bloodborne pathogens, there is a chance of them getting a serious illness or an illness that can put their life at risk.

There are several requirements of OSHA’s bloodborne pathogen standards. These requirements can be found in Title 29 of the code of Federal Regulations at 29 CFR 1910.1030. The requirements of the standard state what should be done by the employers, which is to protect all the workers who are occupationally exposed to blood or other potentially infectious materials or OPIM, as defined in the standard. It means, the standard protects every worker who can reasonably be anticipated to come into contact with blood or OPIM as a result of doing their job duties.

Standards of OSHA

Generally, the employers are required by the OSHA’s bloodborne pathogens standards to do a few things, such as:

- Establishing an exposure control plan to eliminate or to reduce the risk of the occupational exposures. It is a must for the employers to prepare an exposure determination that has a list of job classifications in which every worker has occupational exposure and a list of job classifications in which a few workers have occupational exposure, as well as a list of every task and procedure performed by all the workers that result in their exposure.

- Updating the plan every year to reflect changes in tasks, procedures, and positions that affect occupational exposures. Not only that, they also update the technological changes that get rid or minimize occupational exposure. Besides, it will also be needed for them to document in the plan that they have considered and started using appropriate, commercially-available effective safer medical devices made to get rid or reduce occupational exposure. In addition, they also have to document that they have solicited input from workers who work at the front in identifying, evaluating, and choosing effective engineering and work practice controls.

- Implementing the use of universal precautions.

- Identifying and using engineering controls. They are devices that isolate or get rid of the bloodborne pathogens hazard from the workplace. The list includes sharps disposal containers, self sheathing needles, and safer medical devices, such as sharps with engineered sharps-injury protection and needleless systems.

- Identifying and ensuring the use of work practice controls. They are the practices that minimize the possibility of exposure by changing the method a task is done, such as appropriate practices for handling and disposing of contaminated sharps, handling specimens, handling laundry, and cleaning contaminated surfaces and items.

- Providing personal protective equipment or PPE, including gloves, gowns, eye protection, and masks. It is a must for the employers to do a few things, such as cleaning, repairing, and replacing this equipment as needed.

- Making available hepatitis B vaccinations to every worker with occupational exposure. It is a must for the vaccination to be ordered after the worker has received the required bloodborne pathogens training and within 10 days of initial assignment to a job with occupational exposure.

- Making available post-exposure evaluation and follow-up to any occupationally exposed worker who gets experienced an exposure incident. It is a must for the evaluation and follow-up to be at no cost to the worker and includes documenting the route of exposure and the circumstances.

- Using labels and signs to communicate hazards. It is a must for the warning labels to be affixed to every container of regulated waste, every container of contaminated reusable sharps, every refrigerator and every freezer that has blood or OPIM, every other container that is used to keep, transport, or ship blood or OPIM, every contaminated equipment that is getting shipped or serviced, and every bag or container of contaminated laundry, except as provided in the standard. Instead of labels, the facilities are also allowed to use red bags or red containers. Plus, they have to also post signs at all access doors of the HIV and HBV research laboratories and production facilities when OPIM or infected animals are there in the work area.

- Providing information and training to workers. It is a must for the employers to ensure that their workers get regular training that covers every element of the standard including but not limited to information on bloodborne pathogens and diseases, methods that are used to control occupational exposure, hepatitis B vaccine, and medical evaluation and post-exposure follow-up procedures.

- Maintaining worker medical and training records. It is a must for the employers to maintain a sharp injury log, with the exception if it is exempt under Part 1904 – Recording and Reporting Occupational Injuries and Illnesses, in Title 29 of the Code of Federal Regulations.

A bookworm and researcher especially related to law and citizenship education. I spend time every day in front of the internet and the campus library.